glass bottel jar manual tube semiautomatic powder weighing high viscosity granule controller premade filling sealing machine

Product Description

Fully automatic car oil Filling machine lubricant oil filling machine automatic bottle oil Filling line

Products Description

automatic bottle oil filling line-Product Introduction

The automatic bottle oil filling line is a new type of filling machine meticulously designed by our company. This servo plunger filling machine adopts PLC and touch screen automatic control. It has accurate measurement, stable structure operation, low noise, large adjustment range, and filling Advantages such as fast speed. Moreover, it can adapt to liquids that are volatile, crystallized and foamable; liquids that are highly corrosive to rubber and plastics, as well as high-viscosity liquids and semi-fluids. The measurement is digitally adjusted on the man-machine interface, and the required measurement such as 100ml or 200ml can be set. The touch screen can be reached with one touch, and the measurement can be fine-tuned with a single head.

product name | automatic bottle oil filling line | ||||||

filling head | 16 | ||||||

filling specification | 100-1000ml,1-5L,5-20L | ||||||

suitable for bottle type | glass bottle,PET barrel,PE barrel,can | ||||||

filling speed | 3200 b/h | ||||||

machine size | 4000*2000*2500mm | ||||||

weight | 1200kg | ||||||

anti-drip filling nozzle

PLC touch screen

grease dedicated power system

automatic bottle oil filling line-Product advantages

Adopt dontai specific filling syatem:flowmeter meter type single head single pump single frequency advantage:each filling head has a seperate flowmeter,oil supply pump,rotary encoder,and invorter control,each head can be used as a stand-alone filling system

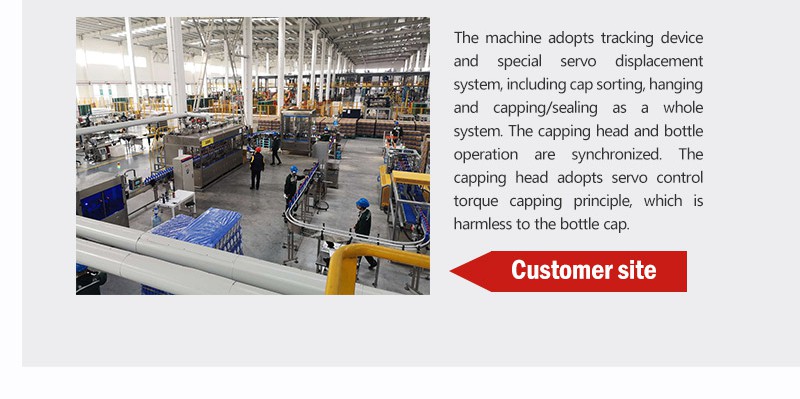

Capping machine-product introduction The automatic capping line is a new type of automatic Production line developed by our company on the basis of absorption technology. It is especially suitable for small and medium-dose liquid filling and various round bottle caps, pump head caps, nozzle caps, duckbill caps, and spray guns. Lock the cover. At the same time, it is suitable for filling and capping of round and special-shaped bottles of various materials, and bottles of various specifications. Microcomputer self-priming peristaltic pump automatic quantitative, pneumatic induction positioning filling (up and down filling structure is optional according to needs), etc. It has the advantages of stable filling, simple operation, high-speed filling and capping. It is widely used in medicine, daily chemical, beverage, wine and other industries.

product name | capping machine | ||||||

capping speed | 3600 b/h | ||||||

dimension | 1800*850*1850mm | ||||||

power | 1000w | ||||||

air compressor | flow rate 01m³/min | ||||||

pressure | 0.4-0.6Mpa | ||||||

oil filling machine fully automatic is suitable for syrup, paint, paint, hydraulic oil, ink, adhesive, curing agent, resin, dye,cleaning agent, machine oil, glycerin, lubricating oil, gear oil, edible oil, fragrance, solvent, auxiliary agent, Motor oil, food additives, pesticides and other hazardous chemicals are filled quantitatively.

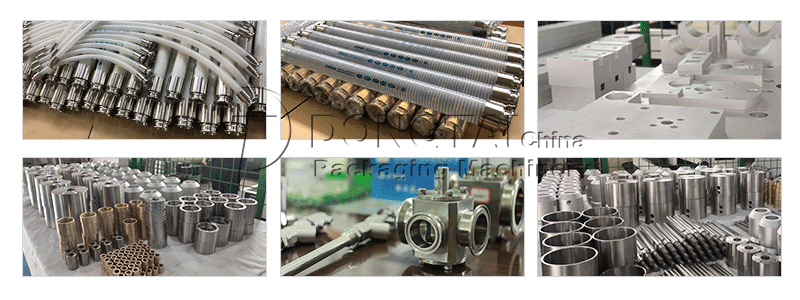

The whole machine is stable and reliable, and the parts and auxiliary equipment of the automatic brake oil filling machine are directly provided by the brand agent. The brand guarantees quality. Imported Airtac cylinders are sturdy and durable. Other seals and other accessories use standard parts that are easy to replace and maintain.

Company Profile

Shandong Dongtai Machinery Manufacturing Co., Ltd. is located in the beautiful Jinan and has five companies under its jurisdiction. Shandong Dongtai Machinery Manufacturing Co., Ltd. is a manufacturer of chemical intelligent equipment. The factory covers an area of 100 acres, a building area of 10,000 square meters, and has more than 150 employees. , We have 12 years of filling experience, and we have obtained ISO9001 quality system certification, ISO14001 environmental management system certification, CE certification and a number of invention patents. The annual output of our company is about 100 production lines, and the sales volume is about 80 sets of equipment. For more than ten years, after the hard work of Dongtai people, Shandong Dongtai Machinery Manufacturing Co., Ltd. has continued to innovate and develop, keep pace with the times, and serve many companies. Provides generations of advanced intelligent packaging equipment to build industrial intelligent factories for customers; provide customers with automated three-dimensional warehouses.

Factory shots

We provideone-stopservices for engineers on site measurement, design drawing, installation and training. Tailored to yourspecialfillingrequirements.We provideone-stopservices for engineers on site measurement, design drawing, installation andtraining.

Exhibitions & customers

At the 10th China Food Machinery and Equipment R&D Exhibition held in 2019, well-known domestic manufacturers have entered the exhibition site. According to statistics from the relevant departments of the organizing committee, the last exhibition received 42,000 professional buyers from all over the country to visit and purchase, and the on-site intentional turnover reached 5 million yuan. Food packaging and processing machinery exhibition to "display technology, promote cooperation, and promote development

Dongtai has established a strategic alliance business relationship with partners all over the world in response to internationaldemand. Its products are sold well in Europe, America, Southeast Asia and other countries and regions, and are received at home and abroad with "excellent quality, excellent service and reasonable price". Customers' favor.

Packing and shipping

Conventional raw material packaging 1. The surface is treated with rust prevention, 2. Inner plastic waterproof packaging, 3. Fix the outer layer of the lubricating oil filling machine with thick wood or steel frame, and then pack it with synthetic board. Combined container transportation, or separate container transportation.

CE certification

All of our filling machine is made of superior spare parts,the processing line assembled strictly according to ISO9001regulation,so our equipment fully in accordance with the GMP&ISO standard production and passed CE certification.

FAQ

Question 1: When was Dongtai Machinery established?

Answer: It started in 2008, and now it has about 12 years of experience in the packaging industry. Q2: What is your delivery time? Answer: It usually takes 30 days to produce, but if there is an emergency, if there are spare parts, it can be completed within 15 days. Question 3: What is the warranty? Answer: The warranty period is 1 year and does not include easily damaged spare parts, such as heaters, belts, etc. Q4: How do you recommend a suitable filling machine to me? Answer: You need to provide us with detailed filling requirements, including the packaged product, bottle size, packaging weight, bottle type, etc. Q5: Can we arrange technicians to debug overseas? Answer: Yes, we can provide services as needed, but the fees you need to pay include: visa fees, round-trip air tickets, accommodation and labor fees. We also accept you to arrange technicians to study in our factory before shipment.Product Categories : Automatic filling machine > Automatic oil filling machine

Premium Related Products

Other Products

Hot Products

Landvac 8mm 4+0.3V+4 Tempered Vacuum Insulated Window GlassLandglass Ld-at Jet Convection Glass Tempering FurnaceLandglass Electric Heating Glass Tempering/Toughening Furnace MachineYMLA522 - Glass Machine For Straight Edge Polishing MachineYMLA522 - Glass Machine For Straight Edge Grinding Machineglass edging machineYMD3 Horizontal Circular Edge Glass Grinding Equipment with 3 wheelsYMW1 Glass Machine for Different Shape Glass Grinding And PolishingYMC251 Glass Beveling Machine with 8 headsGlass Washing Machine YX1200YX1200 Horizontal Glass Washing MachineQJ877 automatic single edge glass grinding machineQJ877 automatic glass grinding pruduct lineCNC400 Glass Cutting Machine for Round Shape GlassYMA231 glass edging&polishing machine for cabinet& bath glassYZ220 semi-automatic horizontal glass drilling machine